Today, the use of advanced farming tools and equipment is essential to improve productivity, reduce labor, and enhance timely agricultural operations. While the tractor is often the centerpiece of mechanized farming, many other tools are also important in various stages of crop production. Below are seven essential agricultural tools and equipment every farmer should be familiar.

1. Rotavator (Rotary Tiller)

The rotavator is a powerful tool used for soil preparation. It is mounted on a power source such as a power tiller or a tractor and is used to break up, churn, and aerate the soil. By turning over the soil, it helps incorporate organic matter and crop residues into the field, which enhances soil fertility and structure.

Rotavators come with various blade configurations suited for different soil types and farming conditions. Their primary function is to reduce soil compaction and create a fine seedbed that supports optimal seed germination. This machine is helpful after harvesting crops like rice and wheat where straw and stubble remain on the field.

Using a rotavator saves time and labor compared to traditional ploughing methods. It also contributes to better moisture retention in the soil and reduces the need for multiple passes over the field. Farmers growing vegetables, pulses, and cereals find rotavators invaluable for pre-sowing land preparation.

Specifications:

- Blade Types: L-type, C-type, J-type

- Working Width: 1.2 to 2.5 meters

- Power Requirement: 25 to 60 HP (depending on size)

- Depth Control: Adjustable

- Mounting: 3-point linkage

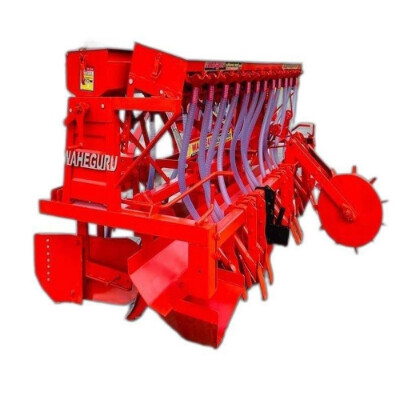

2. Seed Drill

A seed drill is a mechanical device used for sowing seeds at the correct depth and spacing. It improves the efficiency and accuracy of sowing, ensuring that seeds are uniformly distributed across the field. This tool can be manually operated or mounted on a power tiller or animal-drawn plough.

One of the main advantages of using a seed drill is the improvement in germination rates due to even seed placement and proper coverage with soil. It also minimizes seed wastage, which is a common problem in traditional broadcasting methods. For small and medium farmers, using a seed drill can result in cost savings on seeds and enhanced crop yields.

The device comes with adjustable settings that allow farmers to control the depth and rate of seed placement based on the crop type. It is recommended for crops like wheat, maize, soybean, and pulses. When used in combination with a fertilizer attachment, it can also facilitate simultaneous application of nutrients, further boosting productivity.

Specifications:

- Row Spacing: Adjustable (15 cm to 30 cm)

- Number of Rows: 3 to 11 rows

- Seed Metering: Fluted roller or cell-type

- Power Source: Manual, bullock-drawn, or power tiller

- Attachments: Fertilizer box (optional)

3. Power Weeder

Power weeders are essential for inter-cultivation activities, especially for row crops. They help in removing unwanted weeds that compete with crops for nutrients, light, and water. These machines are available in self-propelled or attachment formats and are suited for crops like sugarcane, cotton, vegetables, and pulses.

Weeding by hand is labor-intensive and time-consuming. Power weeders automate the process, significantly reducing manual effort and increasing operational speed. They improve soil aeration, promote root growth, and assist in moisture conservation by reducing surface crusting.

With different types of blades and rotary attachments, power weeders can be customized for different field conditions. They are lightweight, easy to maneuver, and can be operated by a single person. In organic farming, where chemical weed control is not preferred, power weeders play a crucial role in maintaining weed-free fields.

Using a power weeder at the right time not only ensures healthy crop development but also reduces the chances of pest and disease infestation, as many pests breed in weedy environments. Thus, this tool contributes to overall crop health and productivity.

Specifications:

- Engine Power: 3 HP to 7 HP (petrol or diesel)

- Working Width: 20 cm to 60 cm

- Weight: 60 to 120 kg

- Blade Types: L-type, rotary tines

- Fuel Tank Capacity: 2 to 5 liters

4. Sprayer (Manual or Motorized)

Agricultural sprayers are important for the uniform application of pesticides, herbicides, fungicides, and liquid fertilizers. Depending on the farm size and crop type, different types of sprayers are available—manual (knapsack), battery-operated, and motorized versions.

Manual sprayers are cost-effective and suitable for small fields, while motorized sprayers are more efficient for medium to large-scale farms. Battery-operated models combine convenience and consistency and are growing in popularity among progressive farmers. These tools help prevent and control pest and disease outbreaks, ensuring better crop protection.

Proper calibration and usage of sprayers ensure that the chemical reaches all parts of the plant, including undersides of leaves, where pests often hide. Using the correct nozzle and pressure settings prevents chemical wastage and reduces the risk of crop damage or environmental contamination.

A well-maintained sprayer extends its service life and ensures safe usage. Regular cleaning, correct mixing of chemicals, and using protective gear while spraying are essential practices. Advanced models also offer features like pressure regulators and adjustable booms, enhancing their effectiveness and coverage.

Specifications:

- Tank Capacity: 12 to 16 liters (manual), 20 to 100 liters (motorized)

- Pump Type: Piston, diaphragm, or motorized pump

- Spray Lance: Adjustable nozzle

- Power Source: Manual, battery, or engine

- Operating Pressure: 2 to 6 bar

5. Threshing Machine

Threshing machines are designed to separate grains from harvested crop stalks and husks. Traditionally, threshing was done manually using sticks or by trampling with animals, which was laborious and resulted in grain loss. The mechanized thresher revolutionized this process.

These machines come in various sizes and capacities, suitable for smallholder farms to commercial operations. They are used for crops such as paddy, wheat, maize, and millets. Threshers can be stationary or mobile and are powered by diesel engines or electric motors.

The advantages include faster processing time, minimal grain breakage, and reduced post-harvest losses. Many modern threshers are multipurpose, allowing them to handle different crop types with interchangeable parts. This flexibility makes them cost-effective for farmers growing multiple crops.

When combined with harvesters, threshers help in streamlining post-harvest operations and speeding up the process of grain collection and storage. This reduces the risk of spoilage due to delayed processing, during the monsoon season.

Specifications:

- Capacity: 500 kg/hr to 1500 kg/hr

- Power Source: 5 HP to 15 HP engine or electric motor

- Crop Compatibility: Wheat, paddy, maize, pulses

- Output Type: Clean grain, husk separated

- Portability: Stationary or mobile-mounted

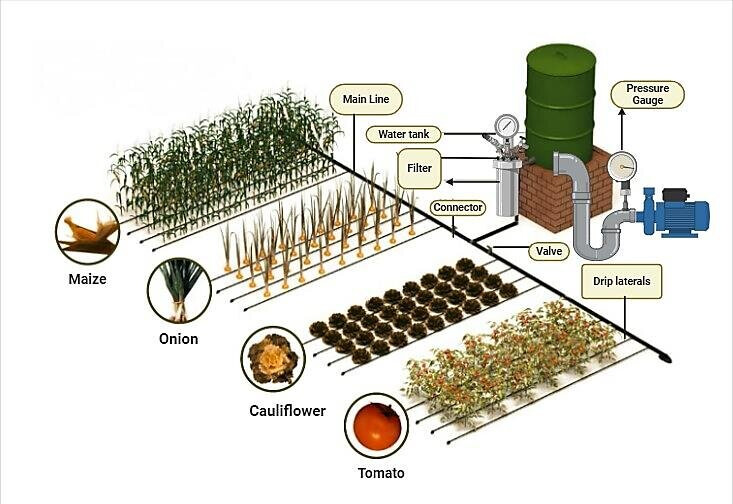

6. Irrigation Pump / Drip Irrigation System

Water management is critical for successful farming. Irrigation pumps help draw water from wells, rivers, or reservoirs and distribute it across fields. Common pump types include centrifugal, submersible, and solar pumps. The choice depends on the water source depth, energy availability, and field size.

Drip irrigation systems, on the other hand, deliver water directly to the root zone of each plant through a network of valves and pipes. This method reduces water usage and prevents waterlogging, soil erosion, and weed growth. It’s especially useful in arid and semi-arid regions where water is scarce.

Government subsidies are often available for drip systems due to their water-saving benefits. These systems also allow fertigation—applying fertilizers through irrigation, which improves nutrient uptake and reduces input costs.

Regular maintenance of irrigation equipment ensures longevity and efficiency. Farmers are encouraged to check for leakages, clogs, and pressure inconsistencies to ensure uniform water distribution.

Specifications:

- Pump Types: Centrifugal, submersible, solar

- Pump Capacity: 1 HP to 10 HP

- Drip System Flow Rate: 1–4 L/hour per emitter

- Pipe Diameter: 12 mm to 32 mm

- Operating Pressure: 1 to 3 bar

7. Multi-Crop Planter

A multi-crop planter is a versatile tool that enables sowing of different seeds like maize, sunflower, groundnut, and soybean with the same machine. These planters ensure precise seed placement, spacing, and depth for various crops by adjusting settings and components.

The primary advantage is time efficiency-farmers can switch between crops without changing equipment. Multi-crop planters reduce seed wastage, labor costs, and ensure uniform crop emergence. Some models also come with fertilizer application attachments, enhancing field productivity.

This equipment is beneficial for progressive farmers practicing crop rotation or intercropping. With better control over seeding operations, farmers can achieve consistent plant stands, which is essential for effective irrigation, nutrient management, and harvesting.

Maintenance involves periodic checking of seed metering mechanisms, lubrication of moving parts, and calibration before each use. Investing in a quality multi-crop planter can deliver long-term benefits in terms of yield and operational efficiency.

Specifications:

- Seed Compatibility: Maize, sunflower, soybean, etc.

- Row Spacing: Adjustable (30–60 cm)

- Seed Metering: Plate, belt, or pneumatic

- Hopper Capacity: 20–50 kg

- Attachment: Fertilizer box (optional)

After integrating these modern tools into their farming systems, farmers can enhance efficiency, reduce drudgery, and achieve better outcomes. Each tool serves a specific function but contributes collectively to improved agricultural productivity and profitability.